In the field of protective apparel manufacturing, choosing the right technical fabric not only affects protective performance but also directly impacts workers’ comfort and productivity.

At Viking, we continuously research and apply high-quality Viking protective fabrics, tailored to suit various working conditions.

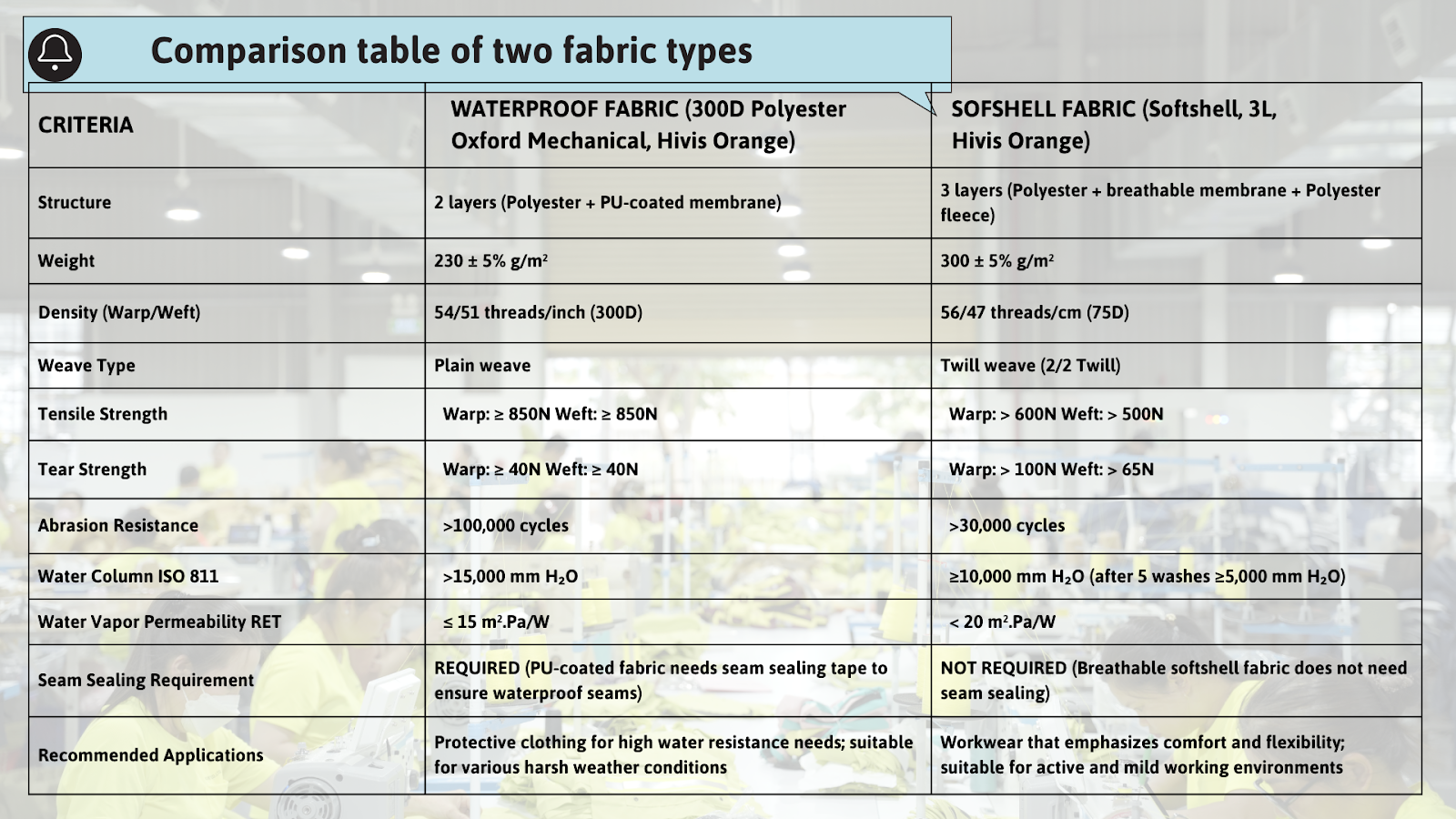

This article helps you differentiate between two commonly used fabrics: Viking two-layer waterproof fabric and Viking three-layer Softshell fabric—and explains how Viking supports and advises customers in selecting the most suitable solution.

Two-Layer Viking Waterproof Fabric – Durable and Purpose-Built

Structure:

Outer layer: Wind-resistant polyester

Inner layer: PU (polyurethane) membrane offering outstanding waterproofness up to 15,000 mm H₂O

Taped seams: Required to ensure full waterproof protection

Applications:

Ideal for outdoor environments with light to moderate rainfall

Widely used in protective jackets and trousers for construction workers, civil engineers

Requires inner lining to protect the thin PU layer from abrasion

Three-Layer Viking Softshell Fabric – Flexible and Breathable

Structure:

Outer layer: Polyester with moderate waterproofness (10,000 mm H₂O)

Middle layer: Wind-resistant and breathable membrane

Inner layer: Fleece lining for excellent insulation

Applications:

Suitable for cold, dry, and windy environments such as warehouses, machinery operations, or night shifts

Ideal for high-mobility garments like jackets for engineers, construction supervisors, and logistics personnel

No seam taping required, reducing production costs

Viking – Custom Solutions, Optimized Performance

At Viking, we understand that every profession and industry has unique protective clothing needs. That’s why Viking is not just a supplier of protective fabrics, but a trusted partner throughout your product development journey:

Personalized fabric recommendations based on actual working environments and industry requirements

Customized protective jacket and uniform designs aligned with your brand image

Optional customization of water resistance levels, lining, color, and technical details

Technical support from sampling to mass production

All export orders follow the strict AQL 2.5 inspection standard

With the motto “Customers at the Center”, Viking always listens, advises, and adjusts designs to best meet real-world demands. We believe our customers' success is Viking’s success.

Viking – Your All-in-One Technical Fabric Solution

Understanding the features and applications of each fabric is essential for designing effective protective uniforms. With our two key fabric lines—Viking waterproof fabric and Viking Softshell fabric—we enable customers to flexibly choose solutions based on specific needs.

Viking is committed to partnering with your business from consulting and design to manufacturing—creating safe, aesthetic, and sustainable garments. If you’re looking for customized, flexible, and standards-compliant protective apparel solutions, contact Viking today!